Roots Blower includes Twin Lobe Roots Blower and Positive Displacement Blowers

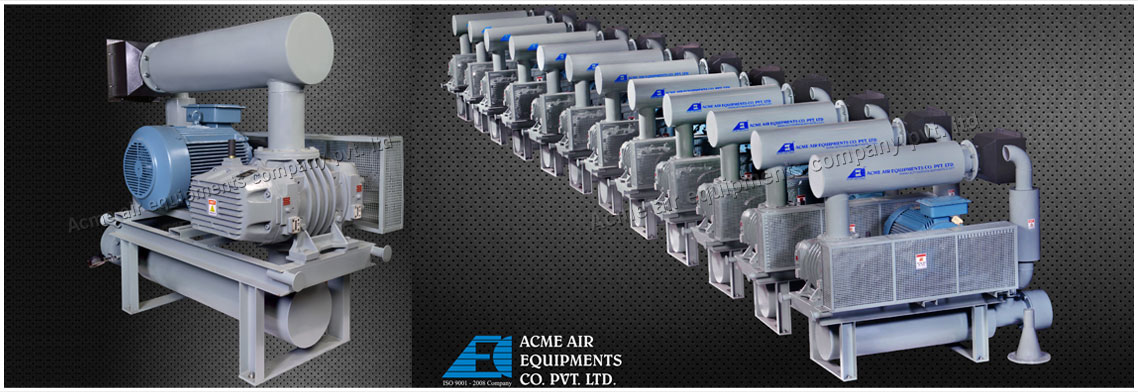

Acme Air Equipments Company Pvt. Ltd. is an ISO 9001-2015 company. We are into full fledged manufacturing of a wide range of Twin Lobe Rotary Compressors / Exhausters. These are also known as Twin Lobe Roots Blower / Vacuum Pump, or pd blowers used in various systems like Mechanical Vapor Recompression as MVR Blower and plants like Sewage Treatment Plants. These twin blowers are High volume-low pressure positive displacement (PD Type) Roots Blowers. The positive displacement rotary lobe blowers operate on differential pressure and constant volume characteristics.

We as two-stage roots blower company manufacture a wide range grouped under air cooled or water cooled design which covers capacities from 10 M³/Hr to 14000 M³/Hr.

We manufacture these machines Twin Lobe Rotary Compressors, positive displacement blowers, MVR Blower in our state-of-the-art modern facility equipped with CNC machines, CAD-CAM software and efficient production control system.

Acme Air Equipments as one of the leading roots blower parts, and two-stage roots blower manufacturers, and exporters and supplier offers only the most efficient technology and quality material in all its equipments.

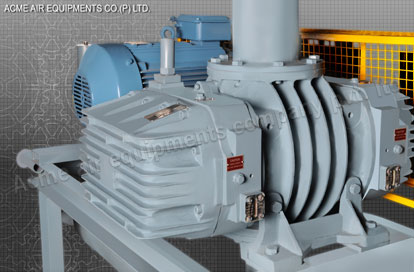

Some of the principal features of our design are:

- Rugged construction

- Lower specific power consumption

- Operate in Overpressure up to 1000 mbar

- Dynamically balanced rotary parts ensure vibration free running.

- Suitable for Continuous Duty

- Operate in Vacuum up to 500 mbar

- Hardened and ground Class 5 Gears

- Oil free conveyance

- Direct coupled or V Belt driven

Some of the common usage of these Roots Blowers is as follows

- Pneumatic Conveying System

- Sewage Treatment Plants

- Central Vacuum Cleaning System

- Aeration in Storage silos

- Charging of Kilns in Cement and Steel Plants

- Blending

- Effluent Treatment Plants

- Dewatering

- Water Treatment Plants

- Air Drying

- Mechanical Vapor Recompression (MVR Blower) etc…

Industries Served with Roots Blower

Cement, Steel, Aluminum, Power, Chemical, Pharmaceutical, Petro-chemical, Food Processing, Dairy, Space, Textile, Construction etc…

Frequently Asked Questions – Twin Lobe Roots Blower

Twin Lobe Roots Blower, also known as a Positive Displacement Blower, is a type of rotary compressor/exhauster that operates on differential pressure and constant volume characteristics. It is designed for high volume-low pressure applications and is commonly used in systems like Sewage Treatment Plants, Effluent Treatment Plants, Waste Water Treatment Plants, Pneumatic Conveying, Coal Injection, Mechanical Vapor Recompression, Ash Handling, Cement Feeding, Dust Collection, Aeration etc.

Acme Air Equipments Twin Lobe Roots Blower offers several notable features, including rugged construction, lower specific power consumption, long life, low noise, low vibration, suitability for continuous duty, the capability to operate in vacuum up to 500 mbar, helical gears, oil-free conveyance and customization of the blower package as per project requirements.

Roots Blowers find applications in various industries and systems. Some common uses include Pneumatic Conveying Systems, Sewage Treatment Plants, Central Vacuum Cleaning Systems, Aeration in Storage Silos, Charging of Kilns in Cement and Steel Plants, Blending, Effluent Treatment Plants, Dewatering, Water Treatment Plants, Air Drying, and Mechanical Vapor Recompression (MVR Blower), among others.

Roots Blowers are utilized in a wide range of industries, including Cement, Steel, Aluminum, Power, Fertilizer, Chemical, Pharmaceutical, Petrochemical, Food Processing, Dairy, Space, Textile, Ceramics and Construction. These blowers offer efficient technology and quality materials to meet the diverse needs of these industries.

Acme Air Equipments manufactures Twin Lobe Roots Blowers in capacities ranging from 10 M³/Hr to 14000 M³/Hr. Our product range covers air-cooled or water-cooled designs, providing options to suit different requirements and applications.

While often used interchangeably, the term twin lobe blower typically refers to machines operating at lower pressures (up to 1,000 mbar or 1 kg/cm²). When the application requires higher pressure or vacuum duties, the equipment is technically classified as a twin lobe compressor. As a leading twin lobe blower manufacturer, we design our units to function efficiently as low-pressure positive displacement compressors, making them suitable for both pressure and vacuum applications in industries like pneumatic conveying and wastewater treatment.

Yes, we specialize in providing complete twin lobe blower assembly packages tailored to your facility’s layout. Our packages typically include the bare shaft blower, motor, base frame, inlet filter/silencer, discharge silencer, pressure relief valve (PRV), and non-return valve (NRV). We can customize the orientation (vertical or horizontal flow) and drive type (V-belt or direct coupled) to match your existing twin lobe air systems.

Sourcing from twin lobe blower manufacturers in India offers a strategic advantage of high-quality engineering at competitive pricing. Indian manufacturers adhere to robust international. We combine advanced CNC machining with rigorous testing facilities to ensure every twin lobe blower meets global performance benchmarks while offering a significantly lower total cost of ownership compared to European or American alternatives.

Absolutely. Our twin lobe air compressor units undergo strict quality checks including hydrostatic pressure testing, mechanical run tests, and performance testing for flow and power consumption. For export orders, we ensure compliance with specific regional requirementsfor oil and gas applications upon request.

We understand the rigors of sea and air freight. All twin lobe air blower units are packed in seaworthy, fumigated wooden crates to prevent corrosion and damage during transit. We work with trusted freight forwarders to offer flexible shipping terms, ensuring your machinery arrives safely whether you are in the Middle East, USA, or Southeast Asia.

Our blowers are designed for durability, but regular maintenance ensures longevity. Key tasks include:

- Checking oil levels in the gear and bearing housing.

- Cleaning or replacing the inlet air filter to prevent choking.

- Checking V-belt tension.

- Greasing the bearings (if applicable). We provide a detailed O&M (Operation & Maintenance) manual with every twin lobe blower manufacturer shipment to guide your local technical team.

Yes, we maintain a robust inventory of critical spares such as timing gears, bearings, oil seals, and gaskets. As a responsible twin lobe blower manufacturer, we can ship spare part kits via air freight to any country.