Acme Air Equipments Company Pvt. Ltd. is an ISO 9001-2015 quality certified company and among the best air booster compressor manufacturers. It is a most trusted and quality manufacturer of Gas Boosters (Booster Compressor), Twin/Tri Lobe Roots Blower and allied systems, established in 1990.

The natural gas is now widely used in many industries like power plants, furnaces, burners, glass manufacturing etc. to name a few. Depending on the variation in the consumption pattern by the different industries connected to the grid; fluctuations occur in the operating pressure. For consistency of quality and productivity it is necessary to maintain constant gas pressure for trouble free running of such installations. As one of the leading compressor booster manufacturers, our state-of-the-art Booster Compressor design fulfills this requirement and suits many applications of the industry.

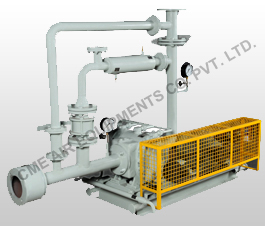

The gas boosters design logic is stipulated in fully automatic mode. When the incoming gas pressure is constant and adequate as per requirement, the booster air compressor system will remain in a stand by position. Whenever incoming gas pressure drops this oxygen booster compressor system will automatically be activated and it will maintain the required pressure.

Features of Gas Boosters

- Auto control

- MOC compatible to handle explosive medium

- Controls suitable for flame proof operation

- Dry working chamber

- Regenerative suction

Frequently Asked Questions – Gas Boosters

Gas Boosters, also known as Booster Compressors, are specialized compressors used to increase the pressure of natural gas in various industries. They are designed to maintain a consistent gas pressure for trouble-free operation in applications such as power plants, furnaces, burners, tile manufacturing, ceramics, and glass manufacturing industries.

The purpose of Gas Boosters is to ensure a constant and adequate gas pressure in industrial installations. They help mitigate fluctuations in operating pressure, ensuring consistent quality and productivity in processes that rely on natural gas. Gas Boosters are particularly useful when there are variations in gas consumption patterns across different industries.

Acme Air Equipments’ Gas Boosters are offered to handle various type of gases like Nitrogen Gas, Biogas, CO2 Gas, Hydrocarbon Gas, Natural Gas

Auto control : The Gas Booster system operates in a fully automatic mode, activating whenever there is a drop in incoming gas pressure.

MOC compatibility : The materials of construction (MOC) used in the gas boosters are compatible with handling explosive mediums, ensuring safety.

Flameproof operation : The controls of the gas boosters are suitable for flameproof operation, providing enhanced safety measures.

Dry working chamber : The gas boosters have a dry working chamber, minimizing the risk of contamination.

Regenerative suction: The boosters utilize regenerative suction, optimizing efficiency and performance.

Yes, Acme Air Equipments’ Gas Boosters are designed to operate for a maximum differential pressure of 1 bar. They are suitable for various industrial applications to handle gases like Natural Gas, Nitrogen Gas, Biogas, CO2 Gas, and Hydrocarbon Gas. They are compatible with industries such as power plants, furnaces, burners, glass manufacturing, and more. The boosters provide reliable pressure and contribute to the smooth operation of these installations.