Acme Air Equipments Company Pvt. Ltd.- ISO 9001-2015 certified liquid ring vacuum pump manufacturers offering a robust, efficient and easy to maintain pump.

A liquid-ring vacuum pump is a type of rotating positive-displacement pump commonly employed as a vacuum pump and sometimes as a gas compressor. Unlike rotary vane pumps, liquid-ring pumps feature vanes that are integral to the rotor, creating a rotating ring of liquid that forms the compression-chamber seal.

This design minimizes friction, with the rotor being the only moving component and sliding friction limited to the shaft seals. These pumps are generally powered by induction motors.

AEC AV series pumps and liquid ring vacuum compressors are rotary machines in which liquid is made to act as piston. A balanced cylindrical rotor with hollow hub and a series of curved blades projecting radially, turns freely in a cylindrical casing which is large in diameter than the rotor. The blades of the rotor are enclosed at the sides thus forming a series of buckets, open at the bottom into the hollow center.

As compared to air vacuum pumps, in Liquid Ring Vacuum Pump operation the casing contains sufficient , usually water (in water ring vacuum pump), which when carried around the periphery of the casing by the rotor blades, forms a solid ring of inside the casing, due to centrifugal force, since the rotor is smaller in diameter than the casing and rotates on a center eccentric to that of the casing, the rotor buckets will be partially empty. As one of the leading roots blower vacuum pump, and liquid ring vacuum pumps manufacturers, we take great care when designing all our vacuum pumps.

The alternatively entering and leaving the rotor buckets at high speed constitutes a series of liquid piston that surge in rapid succession in and out of the rotor buckets. Air enters through the inlet ports of the cone which are located at the point where the surges away form the rotor (A) and into the casing. Discharge ports are at the point in the rotating cycle where the again surges back into the rotor buckets, permitting the compression and discharge of air. This effect is continuous and is repeated numbers of times per minute, producing an un-interrupted air flow without pulsation / vibration.

When the inlet is connected to closed system and the outlet to atmosphere the machine will draw air and gases form the system discharge into the atmosphere and will act as Vacuum Pump.

When the inlet is connected to the atmosphere and the outlet to a close system the machine will draw air from the atmosphere and discharge into the system and will act as Compressor.

When the inlet is connected to closed system and the outlet to atmosphere the machine will draw air and gases form the system discharge into the atmosphere and will act as Vacuum Pump. When the inlet is connected to the atmosphere and the outlet to a close system the machine will draw air from the atmosphere and discharge into the system and will act as Compressor.

We provide all our customers with the top-quality products as a leading vacuum pump company in India, and across the world. Also, Acme Air Equipments Pvt. Ltd. being among the best water ring vacuum pump manufacturers, offers these products at the most competitive prices.

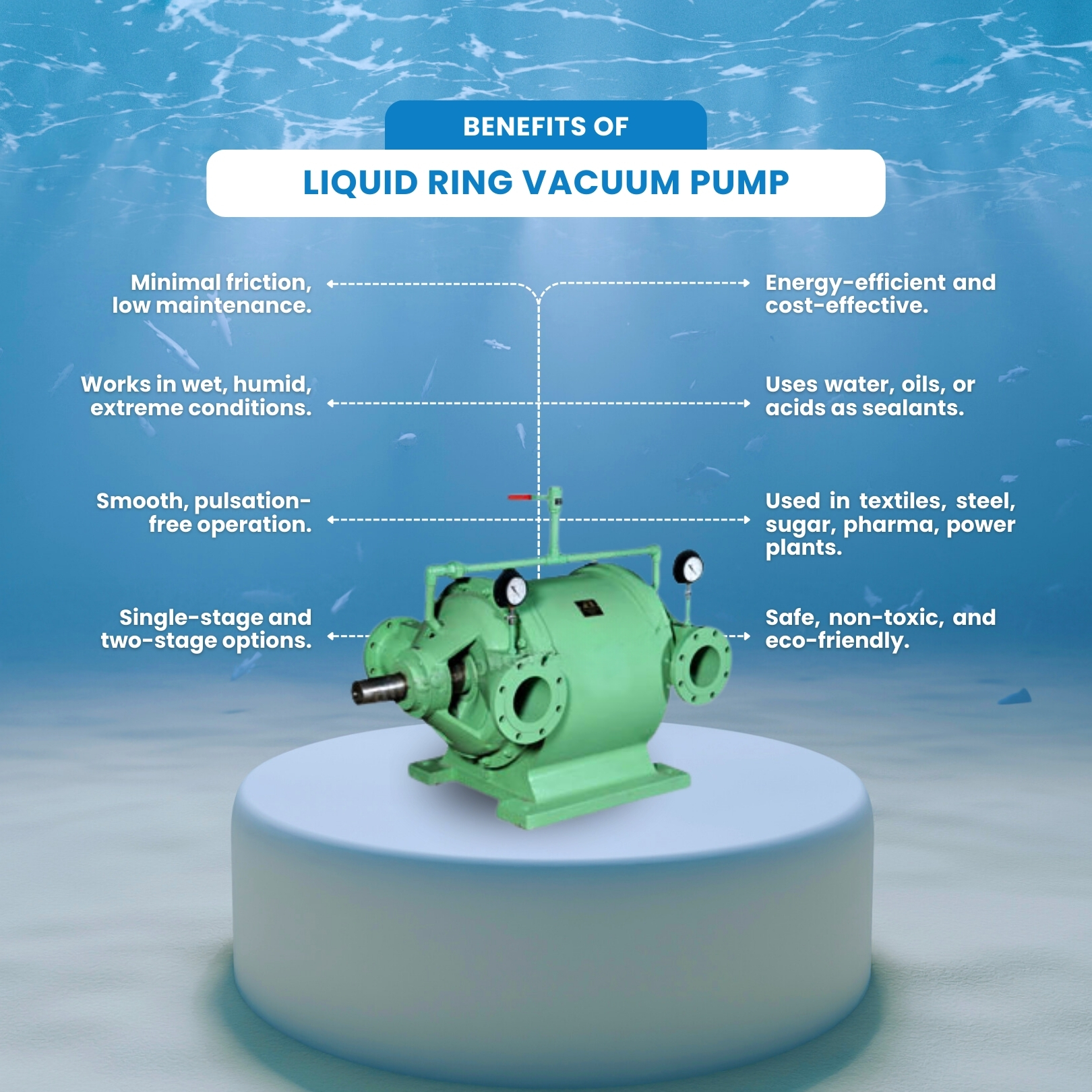

Salient Features of Liquid Ring Vacuum Pumps

Liquid ring vacuum pumps offer several standout features that make them ideal for a wide range of applications:

-

Low-Friction Design: With the rotor being the only moving part and minimal sliding friction, these pumps ensure efficient and durable operation.

Versatile Sealant Fluids: Although water is the most commonly used sealant, liquid ring vacuum pumps can utilize a variety of fluids, including oils and concentrated sulfuric acid, depending on the process requirements.

Robust Performance in Harsh Conditions: These pumps are well-suited for wet, humid, and dirty environments, handling elevated temperatures, extreme vapor loads, and even liquid or solid carryover from processes.

Flexible Operation Modes: Available in single-stage and two-stage versions, these pumps can be configured for continuous flow, partial, or total recirculation systems.

Reliable and Durable: Known for their durability, liquid ring vacuum pumps can operate effectively in the most demanding industrial conditions with minimal maintenance.

Applications – Liquid Ring Pumps

Liquid ring vacuum pumps excel in demanding environments across various industries, including food processing, petrochemicals, and plastics. They are particularly effective in handling wet, humid, and dirty applications, as well as high-temperature and high-vapor-load conditions. These pumps can manage liquid or solid carryover from processes, making them highly versatile for numerous applications.

- Fly Ash Handling

- Textile Industry

- Sugar Industry

- Steel Plants

- Chemical & Pharmaceutical Industry

- Thermal & Atomic power plants

- Mineral Washeries

- Fertilizer plants

Usage of Liquid Ring Vacuum Pumps

Liquid-ring vacuum pumps can utilize any liquid compatible with the process, provided it has suitable vapor pressure properties. While water is the most common sealant, oils are often used due to their low vapor pressure, which makes oil-sealed liquid-ring pumps typically air-cooled. In applications involving dry chlorine gas, concentrated sulfuric acid is commonly used as the sealant.

Frequently Asked Questions – Liquid Ring Vacuum Pump

A liquid ring vacuum pump is a type of rotating positive-displacement pump that is commonly used to create vacuum conditions or compress gases. It operates using a rotor with vanes that form a ring of liquid to seal and compress gas within the pump chamber.

Liquid ring vacuum pumps work by spinning a rotor inside a partially filled casing. The rotor’s vanes push the liquid outward, forming a liquid ring that creates sealed cavities. As these cavities rotate, they change in volume, trapping and compressing the gas before releasing it through the discharge port.

While both water ring and liquid ring vacuum pumps operate on the same principle, the key difference lies in the operating fluid. A water ring vacuum pump specifically uses water as the sealant, whereas a liquid ring vacuum pump can use a variety of liquids, including water, oil, or other suitable fluids, depending on the application.

Selecting the right liquid ring vacuum pump involves evaluating several factors such as the required vacuum level, the type of gas or vapor being pumped, the operating temperature, pressure conditions, and the presence of any contaminants like liquids or solids. Consulting with a pump expert or the manufacturer can help in making an informed decision.

Acme Air Equipments is renowned for its commitment to quality, innovation, and customer satisfaction. They utilize advanced manufacturing techniques and rigorous quality control processes to produce reliable and efficient liquid ring vacuum pumps. Additionally, their extensive industry experience and dedicated customer support make them a preferred choice for many clients.

Acme Air Equipments ensures the quality of its pumps through stringent testing and quality control measures at every stage of production. They use high-grade materials and advanced technology to manufacture pumps that meet international standards. Continuous R&D efforts also contribute to their high-quality offerings.

Purchasing from Acme Air Equipments guarantees you a high-performance, durable product backed by exceptional customer service. Their pumps are designed to handle the toughest industrial applications, and their team provides comprehensive support, from selection and installation to maintenance and repair.

Acme Air Equipments’ liquid ring vacuum pumps are certified to meet various international quality and safety standards. These certifications ensure that their products are reliable, efficient, and safe for use in a wide range of industrial applications. Specific certifications may include ISO 9001 and other industry-specific standards.

Yes, Acme Air Equipments offers customization options to meet the unique requirements of different applications. Their team works closely with clients to understand their needs and provide tailored solutions that optimize performance and efficiency.