Table of Contents

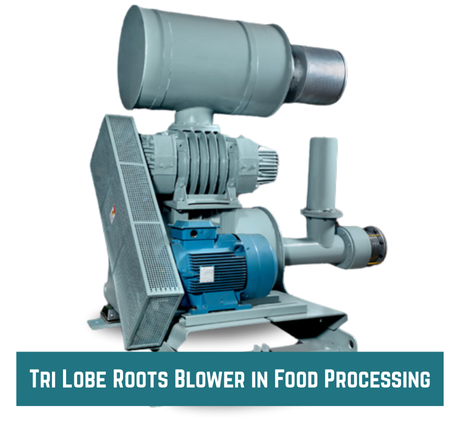

The food processing industry requires high-efficiency equipment to ensure the smooth, continuous and safe movement of materials through various stages of production. One crucial piece of equipment that plays a vital role in maintaining this operational efficiency is the Tri Lobe Roots Blower. Its integration into food processing plants offers several benefits, ranging from improved energy efficiency and enhanced product quality to reduced maintenance costs and operational downtime.

In this article, we explore the significant impact of tri lobe blower design and its integration in food processing plants, shedding light on the role it plays in optimizing various processes, including aeration, conveying and vacuum systems.

What is a Tri Lobe Roots Blower?

A Tri Lobe Roots Blower is a type of positive displacement blower with a distinctive three-lobe rotor design. This design allows for the movement of air or gases through the blower unit at high efficiency, providing continuous airflow with minimal pulsation. Tri lobe blowers are highly valued for their precise performance, low noise levels and energy efficiency compared to traditional blowers, making them ideal for industries such as food processing, where consistent and reliable air supply is critical.

In food processing plants, tri lobe vacuum blowers are commonly used for various tasks such as conveying dry ingredients, aerating products and creating vacuum conditions in packaging lines. Their integration improves operational reliability, product consistency and overall efficiency.

How Does Tri Lobe Roots Blower Integration Improve Operational Efficiency in Food Processing?

Incorporating tri lobe blowers into food processing plants offers significant operational improvements in terms of efficiency, air quality and energy use. These blowers help ensure that processes are not only faster but also more cost-effective.

Improved Airflow Control for Consistent Process Performance

Tri roots lobe blowers offer precise control over airflow, ensuring a consistent supply of air across various stages of food processing. Whether it is for pneumatic conveying of ingredients or providing airflow in fermentation or drying processes, the ability to control airflow precisely means that materials are moved efficiently and processes are optimized.

This level of consistency is especially important in food production, where even slight variations in air pressure or airflow can impact product quality. With tri lobe blowers, food processors can maintain the desired consistency, making it easier to produce high-quality products at scale.

Enhanced Material Handling and Conveying

In food processing plants, the need to transport ingredients, raw materials and finished products across different areas is constant. The tri lobe blower design allows for smooth, continuous material flow, which is critical for the efficient transfer of bulk dry ingredients such as flour, sugar, spices and grains. These blowers provide an effective means of conveying dry materials without the risk of product degradation or contamination.

Tri lobe blowers are particularly effective when conveying materials in dusty or high-volume environments, reducing the risk of blockages and ensuring that production lines continue to function smoothly. The blower design reduces pulsation and minimizes wear and tear, which helps extend the life of equipment and lowers maintenance costs over time.

Improved Vacuum and Aeration Systems

In food processing plants, maintaining the right vacuum and aeration conditions is essential for tasks such as packaging, freeze-drying and fermentation. Tri lobe vacuum blowers are frequently used in these applications due to their ability to create stable vacuum conditions while minimizing energy usage.

For example, in vacuum packaging lines, tri lobe blowers provide the necessary vacuum pressure to seal food products securely, extending shelf life and reducing the need for preservatives. Similarly, in fermentation or aeration processes, these blowers ensure that the right amount of air is introduced, facilitating consistent product development.

Energy Efficiency and Reduced Operational Costs

One of the most significant benefits of integrating tri roots lobe blowers into food processing operations is their energy efficiency. These blowers are designed to consume less power while providing the same or higher levels of airflow compared to traditional blowers. In an industry where energy consumption is a significant part of operational costs, this efficiency translates directly into cost savings.

Tri lobe blowers are engineered to run efficiently even under varying loads, meaning they adjust to the specific demands of the process without wasting energy. This helps food processing plants reduce their overall energy consumption, lowering operating costs and improving profitability in the long run.

Low Noise and Vibration for a Safer Work Environment

In food processing plants, maintaining a quiet and vibration-free environment is crucial for both worker comfort and equipment longevity. Tri lobe blowers are known for their low noise output and smooth operation compared to other types of blowers. This characteristic is essential in large facilities where noise levels can easily become disruptive or even hazardous to workers.

By integrating lobe blowers, food processing plants can reduce noise pollution, contributing to a safer and more comfortable working environment for employees. This not only improves worker satisfaction but also complies with workplace safety standards concerning noise exposure.

What Are the Key Benefits of Tri Lobe Roots Blower Integration in Food Processing Plants?

The integration of lobe roots blowers into food processing plants offers several compelling benefits that can significantly improve overall operations.

Enhanced Product Quality and Consistency

Maintaining the right conditions for material handling, packaging and processing is critical to producing high-quality food products. By providing stable airflow, tri lobe blowers ensure that every stage of the production process is consistent, helping food processors deliver products that meet consumer expectations for taste, texture and appearance.

Improved Safety and Hygiene

In food processing, hygiene is paramount and the risk of contamination must be minimized at every stage of production. The tri lobe blower design ensures that air is filtered, reducing the likelihood of contaminants entering the system. Additionally, integrated dust collection systems reduce airborne particulates that can affect both product quality and worker health.

Reduced Maintenance Costs

Tri lobe roots blowers are known for their durability and low maintenance requirements. The unique design ensures that these blowers have fewer moving parts compared to other types of air-moving equipment, which means there is less wear and tear, reducing the need for frequent repairs or replacements. This durability lowers the total cost of ownership for food processors and ensures smooth operations.

Scalability and Flexibility

As food processing plants grow or adapt to changing market demands, tri lobe blowers provide the scalability needed to keep up with increased production. These blowers are available in a range of sizes and capacities, making them adaptable to a wide variety of applications. Whether a plant is increasing production capacity or modifying processes, tri lobe blowers can be easily integrated to handle new requirements.

When Should Food Processing Plants Consider Tri Lobe Roots Blower Integration?

Food processing plants should consider integrating tri lobe blowers when they face the following challenges:

- Increased Production Demands: As production increases, the need for more efficient air and material handling systems becomes critical. Tri lobe blowers can provide the necessary airflow without compromising performance or energy efficiency.

- High-Volume Material Handling: For plants dealing with bulk materials, particularly those prone to dust or requiring constant flow, tri lobe blowers offer a smooth, reliable solution.

- Need for Energy Savings: When energy consumption becomes a major operational cost, switching to a tri lobe blower can lead to significant savings by reducing power usage while maintaining or increasing output.

- Improving Hygiene and Safety: If current systems are leading to issues with dust, contamination or unsafe air quality, integrating tri lobe blowers can improve air quality and work environment conditions.

Conclusion

The integration of Tri Lobe Roots Blowers into food processing plants represents a powerful upgrade in operational efficiency, product consistency and safety. With their ability to handle material conveyance, aeration, vacuum applications and provide a clean, reliable airflow, these blowers contribute significantly to the smooth running of food production operations.

As food processing plants strive for greater efficiency, scalability and cost reduction, the adoption of tri lobe blowers presents a compelling solution to meet these goals. Their energy efficiency, low maintenance requirements and ability to improve product quality make them an invaluable component in modern food processing systems.

FAQs about Tri Lobe Roots Blowers

What is the advantage of using a Tri Lobe Roots Blower in food processing?

Tri Lobe Roots Blowers offer precise airflow control, energy efficiency, low noise and reduced maintenance, all of which improve operational efficiency and product consistency in food processing.

How does Tri Lobe Blower integration improve product quality?

By providing consistent airflow and stable vacuum conditions, tri lobe blowers ensure that food products are processed under optimal conditions, leading to high-quality and consistent output.

What industries benefit the most from Tri Lobe Roots Blowers?

Industries such as food processing, pharmaceuticals, chemicals and agriculture benefit the most from tri lobe roots blowers due to their high efficiency, reliability and energy-saving capabilities.

Can Tri Lobe Roots Blowers help with dust collection?

Yes, tri lobe blowers are often used in conjunction with dust collection systems to reduce airborne particulates, improving air quality and workplace hygiene.

Are Tri Lobe Roots Blowers energy-efficient?

Yes, tri lobe blowers are known for their energy efficiency, consuming less power while delivering the same or higher levels of airflow compared to traditional blowers.

About Author

CEO

Mr. Vishwesh Pardeshi is the CEO of Acme Air Equipments Company Pvt. Ltd., an industrial and engineering goods manufacturing company based in Ahmedabad, Gujarat (India). He has taken over the responsibility from founding Partners and Directors of the Company, and is now leading a talented group of professionals since 2020 by bringing in vast industrial and management expertise. By qualification, he holds a Bachelor Degree in Mechanical Engineering and also holds a MBA degree from reputed institutes. Under his leadership, the Company has successfully executed prestigious projects by delivering high quality and world class products from a state of the art manufacturing facility which combines CNC-enabled precision manufacturing and strong after sales support. In line with the Vision, Mission and Core Values of the Organization, Mr. Vishwesh Pardeshi continues to drive Quality, Reliability and Global Expansion at Acme Air Equipments Co. Pvt. Ltd.