Table of Contents

Southeast Asia is home to one of the fastest-growing and most dynamic chemical industries in the world. As the demand for chemicals increases, so too does the need for more efficient and reliable production processes. One such process improvement comes in the form of booster compressors, which have become indispensable in the region’s chemical sector.

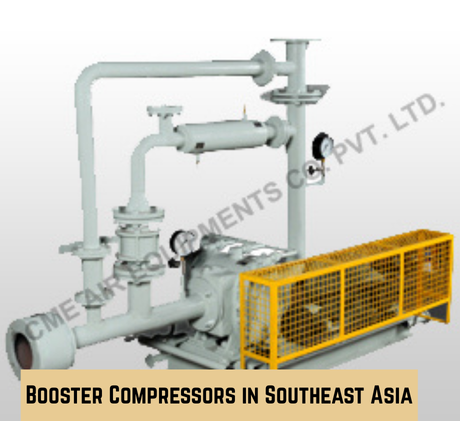

Booster compressors, including air booster compressors, are essential for enhancing pressure in various stages of chemical production. By ensuring consistent, high-pressure airflow and gas supply, these compressors improve efficiency, optimize energy consumption and enhance product quality in chemical plants. The adoption of these advanced systems in Southeast Asia’s chemical industry is accelerating, driven by both the region’s industrial expansion and the need for cost-effective, high-performance equipment.

In this article, we explore how gas compressor are shaping the future of Southeast Asia’s chemical industry, their key benefits and the factors driving their adoption.

What Are Booster Compressors and Why Are They Important in Chemical Plants?

Booster compressors are mechanical devices designed to increase the pressure of gases, such as air, nitrogen or hydrogen, to required levels for industrial processes. These compressors are typically used to raise the pressure of gases beyond the capacity of standard compressors or systems. They play a vital role in applications where precise pressure control is critical, such as in chemical manufacturing, gas transmission and laboratory processes.

The chemical industry, which relies heavily on the transport and handling of gases like oxygen, nitrogen, hydrogen and air, benefits significantly from booster compressor. These systems help maintain the necessary gas pressures for chemical reactions, cooling processes and storage, ensuring smooth and efficient operations.

In the context of Southeast Asia, a region that is increasingly becoming a hub for chemical production, integral in maintaining the high pressures required for processes such as gas liquefaction, distillation and chemical vapor deposition (CVD).

How Do Booster Compressors Improve Efficiency in Southeast Asia’s Chemical Industry?

The adoption in Southeast Asia’s chemical industry is transforming operational efficiency. These systems provide several key advantages, ranging from energy savings to improved productivity and safety.

Energy Efficiency and Cost Savings

In many chemical plants, compressing gases to higher pressures is an energy-intensive process. Traditional methods can be inefficient and lead to increased operational costs. However, energy-efficient booster compressors are designed to optimize energy usage by compressing gases at a lower cost compared to older equipment.

By utilizing advanced technologies, such as variable frequency drives (VFDs) and integrated pressure control systems, can adjust their power consumption according to real-time demands. This flexibility helps reduce wasted energy, ultimately lowering the cost of gas compression in chemical plants. In Southeast Asia, where energy prices can fluctuate, these savings are particularly important for plant operators seeking to maintain profitability while minimizing environmental impact.

Enhanced Process Control and Stability

Precise control over gas pressures is vital in chemical production, where even minor fluctuations can compromise the integrity of the process. Booster compressors provide stable and consistent pressure levels, which help maintain process control and ensure that chemical reactions occur as intended.

Whether used in high-pressure reactors or distillation columns, it ensure that the required gas pressures are consistently maintained, minimizing interruptions and improving overall process stability. This reliability is essential for meeting production targets and maintaining product quality, making a vital component in chemical plants.

Increased Productivity and Reduced Downtime

One of the primary benefits is its ability to keep production running smoothly with minimal downtime. Older compressor systems may require frequent maintenance or repairs, which can lead to significant production delays. Booster compressors, however, are built for durability and reliability, meaning less time spent on maintenance and more time focused on production.

In Southeast Asia’s highly competitive chemical sector, any downtime can lead to lost opportunities and increased costs. The adoption enables chemical plants to run continuously, leading to improved productivity and faster turnaround times.

Versatility across Chemical Applications

From air boosting in pneumatic conveying systems to providing the necessary gas pressure in hydrogen production, Gas Compressors are versatile and can be tailored to a wide range of chemical processes. They are used in applications such as:

- Gas Compression: Compressing gases like nitrogen, oxygen and hydrogen for storage or use in various chemical reactions.

- Distillation and Separation: Maintaining high pressures in distillation columns or separation units, ensuring the separation of chemical compounds under optimal conditions.

- Vapor Deposition: In processes such as chemical vapor deposition (CVD), where high-pressure gases are required to deposit thin films or coatings.

This versatility makes Booster Compressors an essential component in various areas of chemical production in Southeast Asia, where industries are continuously expanding and diversifying.

What Are the Key Drivers of Booster Compressor Adoption in Southeast Asia’s Chemical Industry?

Several factors are contributing to the increased adoption in Southeast Asia’s chemical industry. These include technological advancements, increasing production demands and the region’s growing emphasis on energy efficiency and environmental sustainability.

Rapid Industrialization and Growing Chemical Production

Southeast Asia is experiencing significant industrial growth, with countries like Singapore, Malaysia and Indonesia becoming key players in the global chemical production sector. The region’s expanding chemical industry requires more efficient, reliable and scalable equipment to meet rising production demands. Booster compressors offer the performance needed to support large-scale chemical production while optimizing energy consumption and operational costs.

Technological Advancements in Compressor Design

Recent innovations in compressor design have led to the development of high-performance booster compressors that offer enhanced efficiency, reliability and adaptability. New technologies such as variable speed drives, advanced pressure control and improved materials have enabled to perform better than ever before. These advancements are particularly attractive to chemical plants that want to upgrade their existing systems to meet modern operational demands.

Regulatory Pressures and Environmental Concerns

As Southeast Asia becomes more integrated into global markets, there is an increasing focus on meeting international environmental and safety standards. Chemical plants are under pressure to reduce their carbon footprint and minimize waste, which has led to a growing interest in energy-efficient technologies. These systems help reduce energy consumption, decrease operational waste and lower emissions, contributing to a plant’s overall sustainability.

Economic and Competitive Pressures

Southeast Asia’s chemical industry is highly competitive, with local and international players vying for market share. To stay competitive, chemical plants need to optimize their operations and reduce costs. The adoption of gas compressors is a cost-effective way to achieve these goals. By reducing energy consumption, increasing operational efficiency and lowering maintenance costs, booster compressors help chemical companies maintain profitability and stay ahead in a fast-paced market.

How Are Booster Compressors Transforming Specific Applications in Southeast Asia?

In addition to their general benefits, booster compressors are having a transformative impact on specific applications in the chemical industry across Southeast Asia.

Oxygen and Hydrogen Production

In the production of oxygen and hydrogen, booster compressors are crucial for compressing gases to the required pressure levels for storage and distribution. As green hydrogen production grows in Southeast Asia, the demand for reliable, high-performance gas boosters is increasing. Oxygen gas boosters are also widely used in industries like steel manufacturing and wastewater treatment.

Petrochemical Processing

Petrochemical plants in Southeast Asia rely on gas compressors to maintain high pressures during the refining and production of petrochemical products. By optimizing gas flow and ensuring consistent pressure, these compressors help improve the efficiency of cracking, distillation and other critical processes.

Air Separation and Gas Recovery

In air separation plants, booster compressors are used to compress and transport gases like nitrogen and oxygen. By maintaining stable and high pressure, these compressors ensure the efficiency of gas separation and recovery processes, which are critical for industries ranging from pharmaceuticals to electronics manufacturing.

Conclusion

The adoption of booster compressors in Southeast Asia’s chemical industry is revolutionizing production processes, improving energy efficiency and contributing to sustainability goals. With their ability to handle high-pressure applications, provide stable airflow and reduce energy consumption, booster compressors are becoming an indispensable part of modern chemical production.

As the region continues to grow and evolve, the role of booster compressors in driving operational efficiency, reducing costs and supporting the chemical industry’s demands will only increase. Companies in Southeast Asia that adopt these systems will be better positioned to stay competitive in the global chemical market.

FAQs About Air Booster Compressors

What are booster compressors and how do they work in the chemical industry?

Booster compressors are devices used to increase the pressure of gases in various industrial applications. In the chemical industry, they help improve gas flow and pressure control, ensuring efficient production processes such as air separation, hydrogen production and petrochemical processing.

How do booster compressors improve efficiency in chemical plants?

Gas compressors increase efficiency by maintaining consistent high-pressure airflow, reducing energy consumption and minimizing downtime through enhanced durability and low maintenance requirements.

Can booster compressors help reduce operational costs in chemical plants?

Yes, booster compressors help reduce operational costs by improving energy efficiency, minimizing maintenance and increasing uptime, which ultimately lowers production costs.

What are the main benefits of adopting booster compressors in Southeast Asia's chemical industry?

The main benefits include improved efficiency, reduced energy consumption, enhanced process control and increased productivity, all of which contribute to better operational performance and cost savings.

About Author

CEO

Mr. Vishwesh Pardeshi is the CEO of Acme Air Equipments Company Pvt. Ltd., an industrial and engineering goods manufacturing company based in Ahmedabad, Gujarat (India). He has taken over the responsibility from founding Partners and Directors of the Company, and is now leading a talented group of professionals since 2020 by bringing in vast industrial and management expertise. By qualification, he holds a Bachelor Degree in Mechanical Engineering and also holds a MBA degree from reputed institutes. Under his leadership, the Company has successfully executed prestigious projects by delivering high quality and world class products from a state of the art manufacturing facility which combines CNC-enabled precision manufacturing and strong after sales support. In line with the Vision, Mission and Core Values of the Organization, Mr. Vishwesh Pardeshi continues to drive Quality, Reliability and Global Expansion at Acme Air Equipments Co. Pvt. Ltd.