Table of Contents

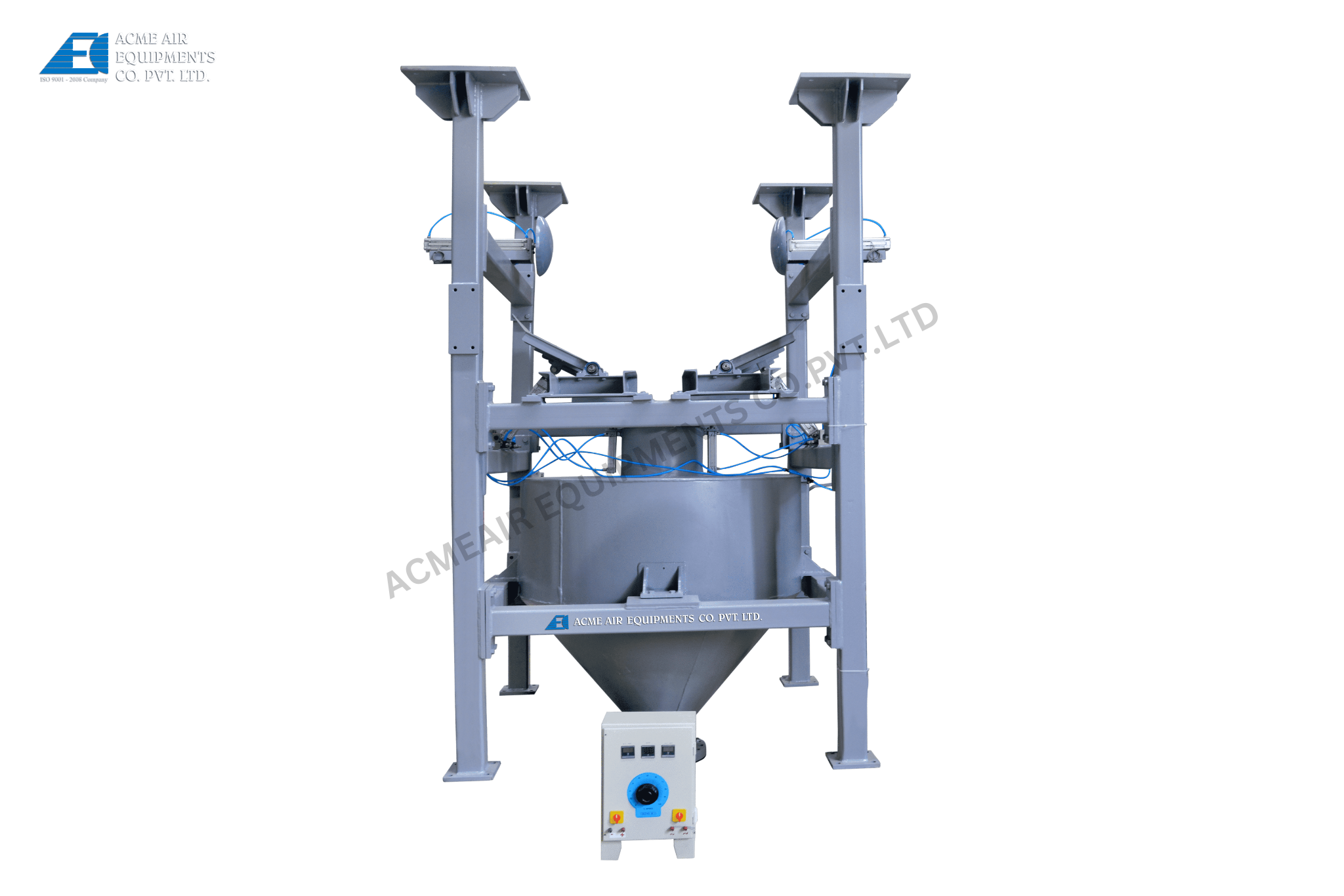

Bulk material unloading, especially from flexible intermediate bulk containers (FIBCs or big bags), presents engineering challenges that require precision, safety and flow reliability. The Big Bag Unloading System, is a purpose-built mechanical solution designed to address these issues.

This system ensures complete and safe material discharge by utilizing a rigid frame for structural integrity and a jostling mechanism for effective material flow, especially when dealing with materials that exhibit poor discharge behavior like cement, catalysts or fly ash.

This article explores how these core components work together to provide reliable, contamination-free and efficient bag emptying operations.

Rigid Frame: Engineered for Load Stability and Safety

The rigid frame forms the structural base of the system and is responsible for supporting the entire weight of the big bag during the unloading process. Typically fabricated from heavy-duty carbon steel or stainless steel, it ensures the following:

- Consistent vertical alignment of the bag for optimal gravity-assisted discharge.

- Load-bearing safety, especially for 1-ton standard bags or larger formats.

- Resistance to vibration stresses induced by jostling or agitation during discharge.

- Compliance with engineering codes like IS, ASME or ISO, depending on end-user specifications.

The frame is precision-designed to eliminate any misalignment that might cause uneven flow or operator hazards. As such, it’s often offered with customizable dimensions to match plant layouts or bag sizes.

Jostling Mechanism: Ensuring Uninterrupted Material Flow

Why Jostling Matters?

In many cases, the contents inside a big bag settle during storage or transport, creating compaction zones that inhibit flow. A jostling mechanism – also known as a massager or agitator – solves this by applying mechanical force to the bag in a controlled manner, thus ensuring uninterrupted flow.

Key Mechanical Components:

- Vibrating Motors: Installed on the frame or platform to generate consistent vibration, promoting particle movement.

- Massaging Arms or Paddles: Pneumatically or mechanically activated arms that knead or press against the sides of the bag.

- Spring-Damper Units: Absorb shock and allow vertical oscillation to assist in bag relaxation.

This combination ensures that the entire bag empties fully without manual intervention, even for materials with poor flow characteristics like fly ash, resin granules or flour.

Bag Handling and Unloading Mechanism

An effective Big Bag Unloader includes features to facilitate the safe and efficient lifting and positioning of big bags:

- Electric Hoist or Forklift Compatibility: Designed for either overhead hoist operation or front-loading via forklift.

- Suspension Frames: Used to hold the bag securely from the loops for vertical loading.

- Quick-Release Clamps: Allow for easy connection/disconnection of the bag spout to the discharge chute.

These design features improve operator safety and reduce bag changeover time.

Big Bag Unloading Offers Controlled Discharge: Ensuring Operational Precision

Beyond simply dumping the material, precise flow control is integral to maintaining batch consistency, dust suppression and material integrity. The discharge unit, typically located beneath the rigid frame, incorporates:

- Sealed spout enclosures with quick-lock clamps to prevent spillage.

- Iris valves or slide gates to regulate discharge rate and provide emergency shut-off.

- Optional screw feeders or rotary valves when fine metering is required downstream.

Discharge mechanisms are customized to work with hoppers, pneumatic lines or feeders and their materials are selected to withstand abrasion, chemical exposure or hygienic requirements.

System Customization: Tailored for Process Requirements

One of the major benefits of systems developed by Acme Air Equipments Pvt. Ltd., a leading Big Bag Unloading System Manufacturer is the ability to customize every aspect of the solution:

- Bag Handling Method: Compatible with electric hoists, forklifts or overhead cranes.

- Frame Height: Adjustable based on bag size or downstream equipment layout.

- Discharge Interface: Configurable for integration with pneumatic, screw or gravity

systems. - Material Selection: Based on environmental and process needs.

This flexibility ensures the system aligns with specific plant conditions, from compact facilities to expansive automated setups.

Compliance with Standards and Quality Checks

A distinguishing feature of robust Big Bag Unloading Systems is its compliance with recognized quality standards and ability to undergo third-party inspections. In line with best manufacturing practices:

- Systems are designed and fabricated to meet the regulatory standards (e.g., ASME, ISO, NACE, IS).

- Full testing and quality assurance is conducted before dispatch.

- Engineering drawings and design documents are made available for approval before manufacturing.

This ensures that the system not only meets operational needs but also satisfies audit, traceability and safety requirements in high-compliance industries.

Conclusion

The Big Bag Unloading System, anchored by its rigid frame and jostling mechanism, stands as a dependable and efficient solution for handling bulk materials in high-volume industrial environments. Its mechanical design ensures safety, flow continuity and cleanliness while allowing a high degree of customization.

From design validation to compliance and testing, every part of the system reflects precision engineering, aimed at delivering maximum efficiency in unloading big bags with minimal manual intervention or material loss.

FAQs about Big Bag Unloading System

What ensures the complete discharge of materials from big bags?

The jostling mechanism applies vibrations or agitation to prevent material bridging and compaction, ensuring complete emptying.

Can the frame be customized for different plant layouts?

Yes, the rigid frame can be tailored in height, width and mounting configuration to suit various industrial setups.

How are materials kept from spilling during discharge?

Sealed discharge spouts with clamping and dust-tight valves ensure a clean, leak-free unloading process.

Are these systems inspected before delivery?

Yes, systems undergo comprehensive testing and may be reviewed by third-party inspection agencies per client requirements.

Is the system suitable for materials with poor flowability?

Yes, the integrated jostling mechanism is specifically designed to improve the flow of cohesive or compacted bulk materials.

About Author

CEO

Mr. Vishwesh Pardeshi is the CEO of Acme Air Equipments Company Pvt. Ltd., an industrial and engineering goods manufacturing company based in Ahmedabad, Gujarat (India). He has taken over the responsibility from founding Partners and Directors of the Company, and is now leading a talented group of professionals since 2020 by bringing in vast industrial and management expertise. By qualification, he holds a Bachelor Degree in Mechanical Engineering and also holds a MBA degree from reputed institutes. Under his leadership, the Company has successfully executed prestigious projects by delivering high quality and world class products from a state of the art manufacturing facility which combines CNC-enabled precision manufacturing and strong after sales support. In line with the Vision, Mission and Core Values of the Organization, Mr. Vishwesh Pardeshi continues to drive Quality, Reliability and Global Expansion at Acme Air Equipments Co. Pvt. Ltd.