Table of Contents

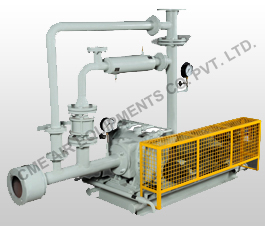

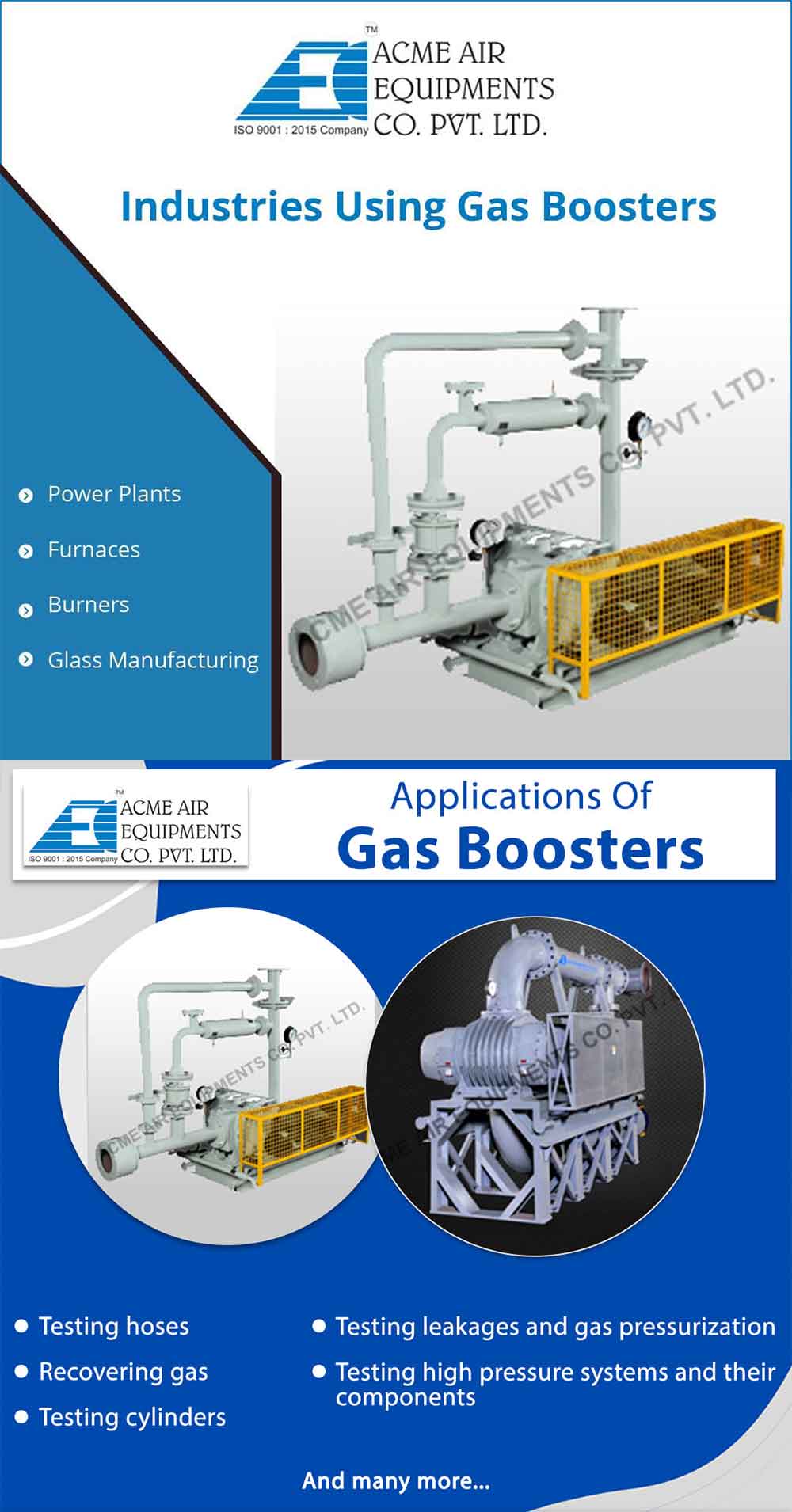

Acme Air Equipments Company Pvt. Ltd. is an ISO 9001:2015 certified company and the leading manufacturer of Gas Boosters and allied systems. Natural gas is used in various industries, and its consumption pattern varies with the grid connection. Constant gas pressure is necessary for achieving consistent quality and trouble-free running of installations. The design logic for a Gas Booster is defined by the compression ratio. The lower the inlet pressure ratio, the higher the boost ratio.

Working Principle of Gas Boosters and Compressors

The pressure and flow rates are fixed in gas boosters. The amount of pressure and flow will depend on the model. Generally, the output pressure is related to the set air drive pressure. The static end-pressure balances the forces in the gas and drives section and suspends air consumption. Upon detecting a change in pressure, the cylinder will automatically restart. If the air supply is interrupted, the cylinder pressure will fall again.

The gas pressure and flow rates are limited by the spool chamber. The discharge pressure is directly proportional to the air drive pressure. By using a gas booster, the outlet pressure can be controlled by adjusting the pilot valves and a special pressure regulator. A static end pressure is necessary for balancing the forces in the drive section and the gas section. Once the static end-pressure is reached, the compressor will automatically restart and continue operation.

Salient Features & Benefits of Gas Boosters and Compressors

The noise levels of a gas booster are highly dependent on the installation and use. However, Acme Air Equipments Pvt. Ltd. has conducted several noise emission measurement tests on its booster. The sound level of the unit was recorded at different heights and distances from the test stand.

The noise level of a gas booster can vary depending on the installation and usage. In some cases, the noise level can be higher than this. Regardless of the type of booster, the sound level will depend on the environment and the type of application. The best option for your needs is the one that is right for your project. If you are looking for a more powerful gas booster, you can contact us today, at https://www.acmeairequipments.com/ to learn more about the different models available.

In Conclusion

Despite their name, gas boosters do not have a lot of noise. Noise levels vary according to the installation and usage. Depending on the type of installation and usage, the noise level of a gas booster will depend on the pressure of the drive air. The higher the pressure, the better the performance. Moreover, the pressure level of a gas booster can also be low. In this way, it is a safe choice for applications requiring high-pressured air.

About Author

CEO

Mr. Vishwesh Pardeshi is the CEO of Acme Air Equipments Company Pvt. Ltd., an industrial and engineering goods manufacturing company based in Ahmedabad, Gujarat (India). He has taken over the responsibility from founding Partners and Directors of the Company, and is now leading a talented group of professionals since 2020 by bringing in vast industrial and management expertise. By qualification, he holds a Bachelor Degree in Mechanical Engineering and also holds a MBA degree from reputed institutes. Under his leadership, the Company has successfully executed prestigious projects by delivering high quality and world class products from a state of the art manufacturing facility which combines CNC-enabled precision manufacturing and strong after sales support. In line with the Vision, Mission and Core Values of the Organization, Mr. Vishwesh Pardeshi continues to drive Quality, Reliability and Global Expansion at Acme Air Equipments Co. Pvt. Ltd.