Acme Air Equipments Company Pvt. Ltd. stands as a pillar of reliability in the industrial machinery sector. Since its establishment in 1990, the company has evolved into a premier manufacturer of high-performance air and gas handling systems.

- ISO 9001:2015 Certification: This is not just a badge; it signifies that Acme’s manufacturing processes-from design to assembly and testing-adhere to rigorous international quality management standards. For a buyer, this guarantees consistency, safety, and durability in critical equipment like Gas Boosters and Roots Blowers.

- Core Expertise: Acme specializes in the core engineering of complex systems like Twin/Tri Lobe Roots Blowers and Gas Booster Compressors, making them a “OEM” (Original Equipment Manufacturer) trusted by global industries.

The Industrial Challenge: Why Natural Gas Pressure Fluctuates

To understand the need for a gas booster, one must first understand the problem with natural gas supply grids.

- The Grid Limitation: Natural gas is supplied through a vast pipeline network. Just like water pressure drops when everyone in a neighborhood turns on their showers at once, gas pressure in the pipeline drops during peak consumption hours.

- The Consequence for Industry: Industries such as Power Plants, Glass Manufacturing, and Industrial Furnaces are extremely sensitive.

- Glass Industry: A drop in gas pressure alters the flame temperature in the furnace, which can cause defects (bubbles or cracks) in the glass.

- Power Plants: Turbines require a precise fuel flow; pressure drops can cause trips or efficiency losses.

- Burners: Inconsistent pressure leads to incomplete combustion, wasting fuel and increasing pollution.

- The Solution: This is where Acme’s technology steps in. You cannot control the grid, but you can control your inlet pressure using a Gas Booster.

The Solution: High-Performance Gas Booster Compressors

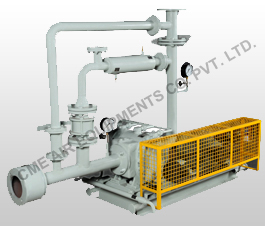

Acme’s Booster Compressor acts as a specialized pump for gas. It sits between the main supply line and your factory equipment. Its primary job is to take gas at low or fluctuating pressure and compress it to a higher, stable pressure required for your specific application.

- Design Philosophy: Acme’s state-of-the-art design focuses on “Trouble-Free Running.” In continuous process industries (like a furnace that runs 24/7), equipment downtime is not an option. The gas boosters are ruggedly built to operate continuously under heavy loads.

How the “Auto-Standby” Logic Works?

The most advanced feature of Acme’s system is its Fully Automatic Logic. This makes the system energy-efficient and autonomous. Here is the step-by-step breakdown of how it works:

- Sensing the Grid: The system is equipped with smart pressure transmitters that constantly monitor the “Incoming Gas Pressure” from the main pipeline.

- Scenario A: Healthy Pressure (Standby Mode): If the pipeline pressure is sufficient (e.g., the grid is supplying 2 bar, and you need 2 bar), the booster recognizes it is not needed. It remains in Standby Position, consuming zero energy. The gas simply bypasses the booster and goes straight to your machine.

- Scenario B: Pressure Drop (Active Mode): If the grid pressure suddenly drops (e.g., to 1.5 bar), the sensor detects the deviation immediately.

- Automatic Activation: The PLC (Programmable Logic Controller) triggers the booster motor. The machine spins up, sucks in the low-pressure gas, compresses it back up to 2 bar, and delivers it to your process.

- Result: Your burners or turbines never “feel” the drop. They continue running smoothly, ensuring consistent product quality.

Gas Booster’s Critical Applications

Acme’s Gas Boosters are engineered to suit a wide variety of demanding applications:

- Power Plants: Boosting gas pressure for gas turbines and gensets.

- Glass & Ceramics: Maintaining precise flame geometry in kilns and lehrs.

- Chemical Processing: Transferring process gases between reactors.

- Metal Processing: Ensuring consistent heat in annealing and hardening furnaces.

Features of Gas Boosters

- Auto control

- MOC compatible to handle explosive medium

- Controls suitable for flame proof operation

- Dry working chamber

- Regenerative suction

Frequently Asked Questions – Gas Boosters

Gas Boosters, also known as Booster Compressors, are specialized compressors used to increase the pressure of natural gas in various industries. They are designed to maintain a consistent gas pressure for trouble-free operation in applications such as power plants, furnaces, burners, tile manufacturing, ceramics, and glass manufacturing industries.

The purpose of Gas Boosters is to ensure a constant and adequate gas pressure in industrial installations. They help mitigate fluctuations in operating pressure, ensuring consistent quality and productivity in processes that rely on natural gas. Gas Boosters are particularly useful when there are variations in gas consumption patterns across different industries.

Acme Air Equipments’ Gas Boosters are offered to handle various type of gases like Nitrogen Gas, Biogas, CO2 Gas, Hydrocarbon Gas, Natural Gas

Auto control : The Gas Booster system operates in a fully automatic mode, activating whenever there is a drop in incoming gas pressure.

MOC compatibility : The materials of construction (MOC) used in the gas boosters are compatible with handling explosive mediums, ensuring safety.

Flameproof operation : The controls of the gas boosters are suitable for flameproof operation, providing enhanced safety measures.

Dry working chamber : The gas boosters have a dry working chamber, minimizing the risk of contamination.

Regenerative suction: The boosters utilize regenerative suction, optimizing efficiency and performance.

Yes, Acme Air Equipments’ Gas Boosters are designed to operate for a maximum differential pressure of 1 bar. They are suitable for various industrial applications to handle gases like Natural Gas, Nitrogen Gas, Biogas, CO2 Gas, and Hydrocarbon Gas. They are compatible with industries such as power plants, furnaces, burners, glass manufacturing, and more. The boosters provide reliable pressure and contribute to the smooth operation of these installations.