Table of Contents

Water ring vacuum pumps play a pivotal role in various industrial applications, with their significance particularly pronounced in the chemical industry. Understanding their working principles, types, applications, and advantages is crucial for industries aiming to optimize their processes efficiently.

Introduction

In the vast landscape of industrial equipment, water ring vacuum pumps stand out as indispensable tools. Within the chemical industry, these pumps are instrumental in creating and maintaining the required vacuum levels for a multitude of processes.

How Water Ring Vacuum Pumps Work

At their core, water ring vacuum pumps operate on the principle of creating a partial vacuum by using a liquid ring. This liquid, often water, serves as both the sealing and working fluid. The pump’s components, including the impeller and casing, work harmoniously to achieve the desired vacuum.

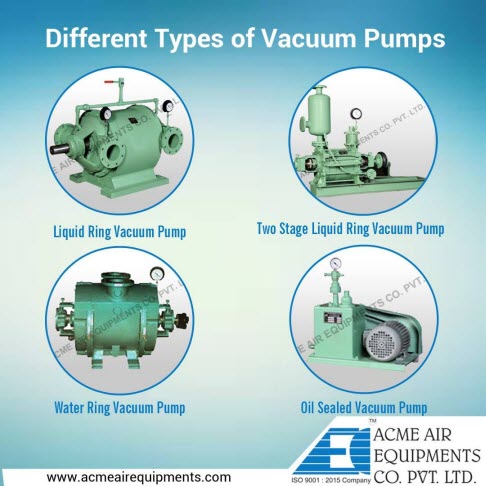

Types of Water Ring Vacuum Pumps

Understanding the distinctions between single-stage and multi-stage pumps is crucial. Additionally, the utilization of liquid ring compressors presents a dynamic choice for specific applications within the chemical sector.

Applications in the Chemical Industry

Water ring vacuum pumps find diverse applications in the chemical industry. From facilitating evaporation processes to aiding in vacuum distillation and supporting filtration and drying processes, their versatility is unmatched.

Advantages of Water Ring Vacuum Pumps

The robust and reliable nature of water ring vacuum pumps, coupled with minimal maintenance requirements, makes them a preferred choice. Their environmentally friendly operation aligns with the growing emphasis on sustainable industrial practices.

Challenges and Solutions

Dealing with process contaminants and overcoming heat dissipation issues are challenges that operators may face. However, advancements in pump design and technology offer effective solutions to these hurdles.

Future Trends

As technology continues to evolve, water ring vacuum pumps are not exempt from innovation. Exploring emerging trends and advancements ensures industries stay ahead in optimizing their processes.

Selecting the Right Pump for Your Application

Choosing the right water ring vacuum pump involves considering factors such as capacity, efficiency, and the nature of the chemical processes involved. Consulting with experts in the field can provide invaluable guidance.

Maintenance Tips for Water Ring Vacuum Pumps

Regular inspections, proper lubrication, and seal checks are essential for maintaining the optimal performance and longevity of water ring vacuum pumps.

Safety Considerations

Given the often hazardous nature of chemicals involved, prioritizing operator safety is paramount. Implementing safety measures and training protocols is non-negotiable.

Environmental Impact

In an era where sustainability is a key concern, water ring vacuum pumps contribute positively to the chemical industry’s environmental footprint. Their energy efficiency aligns with green practices.

Cost Analysis

While the initial investment in water ring vacuum pumps may seem substantial, a comprehensive cost analysis reveals significant long-term benefits and a favorable return on investment.

Industry Regulations and Compliance

Meeting industry standards and complying with regulatory guidelines are imperative. Understanding the implications of these regulations on pump usage ensures seamless operations without legal complications.

Conclusion

Water ring vacuum pumps play a pivotal role in optimizing processes within the chemical industry. Their versatility, coupled with environmental and economic advantages, makes them an integral component for industries striving for efficiency and sustainability.

FAQs About Water Ring Vacuum Pumps Applications

Water ring vacuum pumps are versatile but consulting with experts is crucial to ensure compatibility with specific chemicals.

Regular inspections and maintenance checks are recommended, with frequency depending on usage and environmental conditions.

Yes, water ring vacuum pumps can handle high temperatures, but it’s essential to consider heat dissipation solutions.

Operator training, proper handling of chemicals, and adherence to safety protocols are essential for safe pump operation.

Depending on the region, some governments offer incentives for adopting eco-friendly industrial practices, including the use of water ring vacuum pumps.