Table of Contents

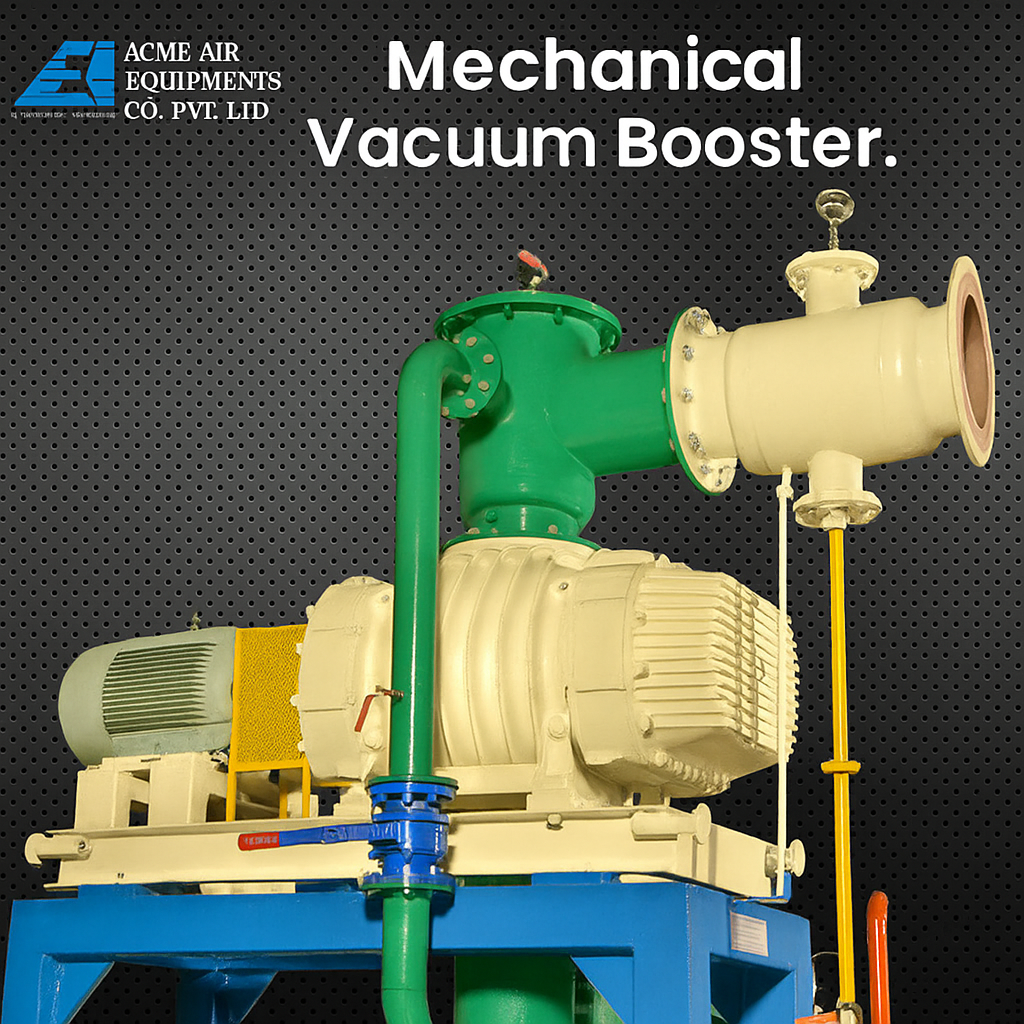

When it comes to optimizing industrial processes, the right choice of vacuum system can make all the difference. The mechanical vacuum booster is a crucial component in a variety of industries that require high-efficiency vacuum pumps. However, selecting the right mechanical vacuum booster for your specific industry needs involves more than simply choosing the most powerful or cost-effective option. This guide outlines the key considerations for selecting the right mechanical vacuum booster for your industry, ensuring efficiency, durability and cost-effectiveness.

Mechanical vacuum boosters are widely used in industries such as automotive, manufacturing, pharmaceuticals and packaging. These systems are designed to improve the efficiency and performance of vacuum pumps by increasing the overall vacuum capacity. Selecting the right vacuum booster is crucial for optimizing your operational workflow. It can impact everything from energy consumption to maintenance costs and overall system performance.

But how exactly do you choose the right mechanical vacuum booster for your industry requirements? This guide will provide you with the knowledge and tools to make an informed decision.

What Are the Key Factors to Consider When Choosing a Mechanical Vacuum Booster?

When selecting a mechanical vacuum booster, there are several factors to keep in mind. These factors determine how well the booster will perform in your specific application:

- System Requirements: Understand the pressure and vacuum levels your process needs to operate at. Different vacuum boosters can operate at varying pressure levels, so it’s essential to match the system’s capabilities with your requirements.

- Flow Capacity: The flow capacity of the vacuum booster should align with the needs of your application. The larger the flow capacity, the more efficiently your system will operate, especially in large-scale industrial applications.

- Energy Efficiency: Energy consumption is an ongoing operational cost. Opt for mechanical vacuum boosters that are designed for energy efficiency to reduce long-term costs.

- Material Compatibility: Ensure that the materials used in the construction of the vacuum booster are compatible with the substances they will come into contact with, especially in industries like pharmaceuticals or food processing.

How Do Mechanical Vacuum Boosters Work?

Mechanical vacuum boosters enhance the performance of mechanical vacuum pumps by increasing the vacuum level or pressure in a system. The working mechanism typically involves an impeller or turbine that spins to increase the flow of gas or air through the system. As the air passes through the booster, the vacuum pressure increases, which improves the efficiency of the entire vacuum system. This makes the mechanical vacuum boosters an essential component for industries where maintaining a high level of vacuum is critical.

How Can You Optimize the Performance of a Mechanical Vacuum Booster System?

To maximize the efficiency of a mechanical vacuum booster system, consider the following tips:

- Regular Maintenance: Regular maintenance ensures that the vacuum booster operates at peak efficiency. Check for wear and tear, ensure proper lubrication and clean filters as needed.

- Monitor Operating Conditions: Keep an eye on temperature, pressure and flow rates to detect potential issues early on. Regular monitoring helps identify any inefficiencies or problems before they impact operations.

- Ensure Proper Installation: Ensure that the mechanical booster is properly installed and calibrated to meet the system’s specifications. Incorrect installation can lead to decreased performance and increased wear.

What Industries Benefit from Using a Mechanical Vacuum Booster?

Mechanical vacuum boosters are indispensable in a variety of industries. Here are a few examples of sectors that benefit from their use:

- Automotive Industry: In automotive manufacturing, vacuum boosters play a crucial role in assembly lines, where they support processes such as molding, painting and testing.

- Pharmaceutical Industry: The pharmaceutical industry uses vacuum systems for processes like drying, sterilization and filtration. A mechanical vacuum booster ensures consistent and efficient operations.

- Food Processing and Packaging: Mechanical vacuum boosters are used to maintain low-pressure environments, crucial for food preservation and packaging.

- Semiconductor Manufacturing: In semiconductor production, vacuum systems are essential for controlling the production environment. A reliable mechanical vacuum booster ensures high precision in the process.

How Do You Choose the Right Size of Mechanical Vacuum Booster for Your Needs?

Selecting the right size of mechanical vacuum boosters depends on several factors:

- Vacuum Requirements: Calculate the desired vacuum level and the flow rate needed for your specific processes. A larger system may be required for more demanding applications.

- Available Space: Consider the available space for installation. Larger vacuum boosters require more space, so ensure your facility can accommodate them.

- System Compatibility: Ensure the vacuum booster you choose is compatible with the rest of your system, including the vacuum pump and other components.

Conclusion

Choosing the right mechanical vacuum booster for your industry is essential for optimizing performance, reducing costs and maintaining high-quality output. By understanding the key factors, types and benefits of mechanical vacuum boosters, you can make an informed decision that suits the specific needs of your industry. Whether you’re in the automotive, pharmaceutical or food processing industry, the right mechanical vacuum booster system will improve the efficiency and reliability of your operations.

FAQs on Mechanical Vacuum Booster

What is a mechanical vacuum booster?

A mechanical vacuum booster is a device used to enhance the performance of vacuum pumps by increasing vacuum levels or pressure, improving the overall efficiency of the system.

How to know if we need a vacuum booster?

If your system requires higher vacuum pressures or flow rates than a standard vacuum pump can provide, a mechanical vacuum booster can help improve system performance.

What industries use mechanical boosters?

Mechanical vacuum boosters are used in industries such as automotive manufacturing, pharmaceuticals, food processing and semiconductor production.

How to maintain a mechanical vacuum booster system?

Regular maintenance includes checking for wear, ensuring proper lubrication and cleaning filters. Monitoring operating conditions such as pressure and temperature can also help detect potential issues early.

About Author

CEO

Mr. Vishwesh Pardeshi is the CEO of Acme Air Equipments Company Pvt. Ltd., an industrial and engineering goods manufacturing company based in Ahmedabad, Gujarat (India). He has taken over the responsibility from founding Partners and Directors of the Company, and is now leading a talented group of professionals since 2020 by bringing in vast industrial and management expertise. By qualification, he holds a Bachelor Degree in Mechanical Engineering and also holds a MBA degree from reputed institutes. Under his leadership, the Company has successfully executed prestigious projects by delivering high quality and world class products from a state of the art manufacturing facility which combines CNC-enabled precision manufacturing and strong after sales support. In line with the Vision, Mission and Core Values of the Organization, Mr. Vishwesh Pardeshi continues to drive Quality, Reliability and Global Expansion at Acme Air Equipments Co. Pvt. Ltd.