Table of Contents

In the fast-paced world of industrial processes, efficiency and reliability are paramount. One technology that has consistently proven its worth in meeting these demands is the Liquid Ring Vacuum Pump. This article delves into its inner workings, advantages over traditional pumps, diverse applications, and the crucial role it plays in various industries.

Introduction

Understanding the basics is essential. A Liquid Ring Vacuum Pump, at its core, operates on the principle of creating a low-pressure environment using a rotating liquid ring. This method not only ensures a reliable vacuum but also contributes to lower maintenance costs compared to traditional alternatives.

How Does Liquid Ring Vacuum Pump Work?

The liquid ring, often water, rotates within the pump casing due to centrifugal force, creating a low-pressure zone that effectively evacuates air or gases. This simplicity in design translates into a pump that is not only efficient but also requires minimal maintenance over its lifespan.

Liquid Ring Vacuum Pump Advantages Over Traditional Pumps

One of the standout features is the significantly lower maintenance costs associated with Liquid Ring Vacuum Pumps. Unlike intricate alternatives, the design simplicity reduces the likelihood of breakdowns, saving both time and money in the long run. Additionally, these pumps are known for their energy efficiency, contributing to cost savings and a reduced environmental footprint.

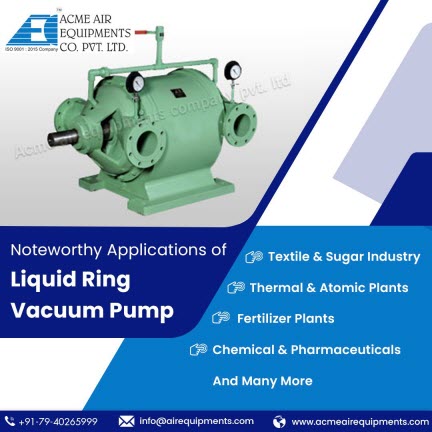

Liquid Ring Vacuum Pump Applications Across Industries

The versatility of Liquid Ring Vacuum Pumps extends across various industries. From chemical processing and pharmaceutical manufacturing to applications in the food and beverage sector, these pumps have proven indispensable in creating the required vacuum for diverse processes.

Liquid Ring Vacuum Pump Maintenance Tips for Longevity

While the maintenance is low, routine inspections and lubrication are key to ensuring the pump’s longevity. This section provides insights into proactive measures and troubleshooting common issues, empowering users to get the most out of their investment.

Comparing with Other Vacuum Solutions

To truly understand the benefits, a comparison with other vacuum solutions is necessary. We explore how Liquid Ring Vacuum Pumps stack up against piston pumps, rotary vane pumps, and scroll pumps, offering a comprehensive view for decision-makers.

Environmental Impact

In an era where sustainability is a priority, the article discusses the environmental impact of Liquid Ring Vacuum Pumps. With lower energy consumption and eco-friendly features, these pumps align with the global shift towards greener industrial practices.

Selecting the Right Liquid Ring Vacuum Pump

Choosing the right pump involves considering factors like capacity, suction pressure requirements, and material compatibility. This section provides guidance to industry professionals, ensuring they make informed decisions based on their specific needs.

Future Trends in Liquid Ring Vacuum Technology and Innovations

As technology advances, so do vacuum solutions. The article explores future trends and innovations in Liquid Ring Vacuum Pumps, providing a glimpse into the potential advancements that could further revolutionize industrial processes.

Bustiness in Industrial Vacuum Solutions

Bustiness, the ability to meet sudden high demands, is a crucial factor in industrial settings. Liquid Ring Vacuum Pumps excel in this aspect, ensuring adaptability in varied environments and maintaining efficiency under challenging conditions.

Addressing Perplexity in Vacuum Pump Selection

Selecting the right vacuum pump can be perplexing, considering the myriad options available. This section addresses common challenges faced by industry professionals and provides solutions for better decision-making.

In-Depth Look at Centrifugal Force

Understanding the role of centrifugal force in creating a vacuum is key to appreciating the pump’s performance. This section delves into the science behind it, offering a detailed look at the forces at play.

Maintaining Efficiency Through Routine Inspections

Proactive measures are vital for maintaining efficiency. This section emphasizes the importance of routine inspections in extending the lifespan of pump components, ensuring a consistently reliable performance.

Conclusion

In conclusion, the Liquid Ring Vacuum Pump stands out as a reliable, efficient, and cost-effective solution for low-pressure vacuum needs in various industries. Its simplicity in design, low maintenance requirements, and versatility make it a valuable asset for businesses aiming for operational excellence.

FAQs About Liquid Ring Vacuum Pump

Regular inspections are recommended, ideally on a quarterly basis, to ensure optimal performance.

Material compatibility is crucial. Some pumps are designed to handle corrosive gases, so it’s essential to select the right model.

While not crucial for all, bustiness is a significant factor in industries with fluctuating demand for vacuum.

Common issues include seal leakage and cavitation, which can be addressed through regular maintenance and proper troubleshooting.

Yes, the adaptability of these pumps makes them suitable for both small-scale and large-scale industrial operations.