Table of Contents

Roots blowers, also known as rotary lobe compressors, have become indispensable across a spectrum of industries due to their efficiency and versatility. These robust machines find diverse applications, ranging from pneumatic conveying systems to sewage treatment plants, catering to the specialized needs of industries worldwide.

One of the primary uses of Roots blowers is in pneumatic conveying systems. These systems efficiently transport bulk materials such as grains, powders, and granules through pipelines, facilitating seamless material handling in industries like cement, steel, and food processing.

Sewage treatment plants rely on Roots blowers for aeration, a crucial process in wastewater treatment where oxygen is infused into the water to support aerobic microbial activity. The constant airflow provided by Roots blowers ensures effective treatment, contributing to cleaner waterways and a healthier environment.

Central vacuum cleaning systems benefit from the powerful suction capabilities of Roots blowers, enabling thorough cleaning in industrial settings such as warehouses, manufacturing facilities, and food processing plants. These systems efficiently remove dust, debris, and contaminants, maintaining cleanliness and hygiene standards.

In storage silos, Roots blowers aid in aeration to prevent material compaction and ensure consistent product quality. Additionally, they play a vital role in the charging of kilns in cement and steel plants, providing the necessary airflow for combustion and temperature control during the production process.

Blending operations in industries such as chemical, pharmaceutical, and food processing rely on Roots blowers to mix ingredients effectively and achieve desired product formulations. The precise airflow control offered by these blowers ensures uniform blending, enhancing product consistency and quality.

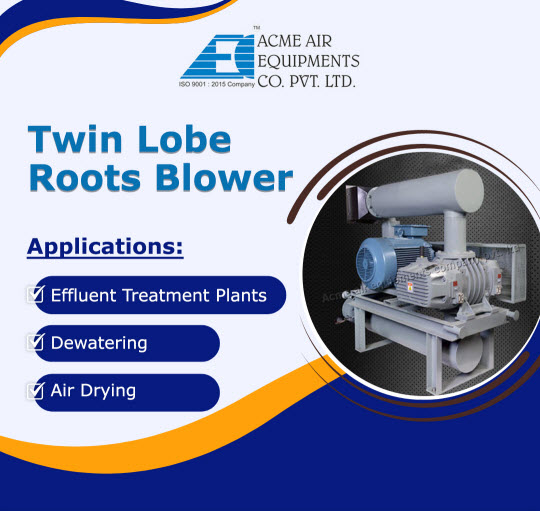

Effluent treatment plants utilize Roots blowers for dewatering processes, where excess moisture is removed from sludge or wastewater, facilitating easier disposal or further treatment. Similarly, in water treatment plants, these blowers aid in aeration and agitation, promoting efficient contaminant removal and water purification.

Roots blowers also find applications in air drying processes, where moisture removal is essential for preserving product integrity and quality. Furthermore, in mechanical vapor recompression (MVR) systems, these blowers play a pivotal role in recovering and recycling steam, contributing to energy efficiency and cost savings in various industrial processes.

The versatility of Roots blowers extends across multiple industries, including cement, steel, aluminum, power generation, chemical processing, pharmaceuticals, petrochemicals, food processing, dairy, textiles, construction, and even space exploration. Their robust construction, reliable performance, and adaptability make them indispensable assets in modern industrial operations.

In conclusion, Roots blowers have emerged as indispensable components across a wide range of industries, facilitating critical processes such as material handling, wastewater treatment, cleaning, blending, and drying. Their versatility, efficiency, and reliability continue to drive innovation and progress across diverse industrial sectors, underscoring their significance in the modern industrial landscape.

FAQs – Roots Blowers

Roots blowers, also known as rotary lobe compressors, are positive displacement machines that generate airflow by trapping and transporting air or gas between rotating lobes. They are widely used for applications requiring continuous, pulsation-free airflow.

Roots blowers consist of two lobes that rotate in opposite directions within a casing. As the lobes rotate, they create chambers that trap air or gas and transport it from the inlet to the outlet. The constant rotation of the lobes ensures a continuous flow of air or gas without compression.

Roots blowers are used in various industries for applications such as pneumatic conveying systems, sewage treatment plants, central vacuum cleaning systems, aeration in storage silos, kiln charging in cement and steel plants, blending operations, effluent treatment plants, dewatering, water treatment plants, air drying, and mechanical vapor recompression (MVR).

Roots blowers cater to a wide range of industries including cement, steel, aluminum, power generation, chemical processing, pharmaceuticals, petrochemicals, food processing, dairy, textiles, construction, and even space exploration. Their versatility makes them indispensable in diverse industrial processes.

Roots blowers offer several benefits including high efficiency, reliability, low maintenance requirements, and consistent airflow. They can handle various types of gases and operate in harsh environmental conditions, making them ideal for demanding industrial applications.

Unlike centrifugal compressors, which rely on high-speed impellers to generate airflow, Roots blowers operate at lower speeds and provide pulsation-free airflow. Additionally, Roots blowers do not compress the air or gas they transport, making them suitable for applications where compression is not required.

When selecting a Roots blower, factors such as flow rate, pressure requirements, operating conditions, power consumption, and maintenance considerations should be taken into account. It’s essential to choose a blower that meets the specific requirements of the intended application.

To ensure optimal performance and longevity, Roots blowers should be properly installed, operated, and maintained according to manufacturer recommendations. Regular inspections, lubrication, and replacement of worn components are essential to prevent downtime and costly repairs.

Yes, Roots blowers can be customized to meet the specific requirements of different applications. Customization options may include varying sizes, materials of construction, sealing arrangements, and accessories to enhance performance and efficiency.

Roots blowers are designed to be energy-efficient and produce minimal emissions, making them environmentally friendly compared to other types of compressors. Their efficient operation contributes to energy savings and reduced environmental impact in industrial processes.