Table of Contents

Germany’s pulp and paper industry is one of the largest and most advanced industry, serving diverse markets from packaging to high-quality printing papers. Vacuum filtration is a key process used in pulp and paper production to separate solids from liquids. Liquid ring vacuum pumps, particularly two-stage designs, play an essential role in this process. By providing high vacuum levels and stable performance, two-stage liquid ring vacuum pumps contribute significantly to both process efficiency and product quality.

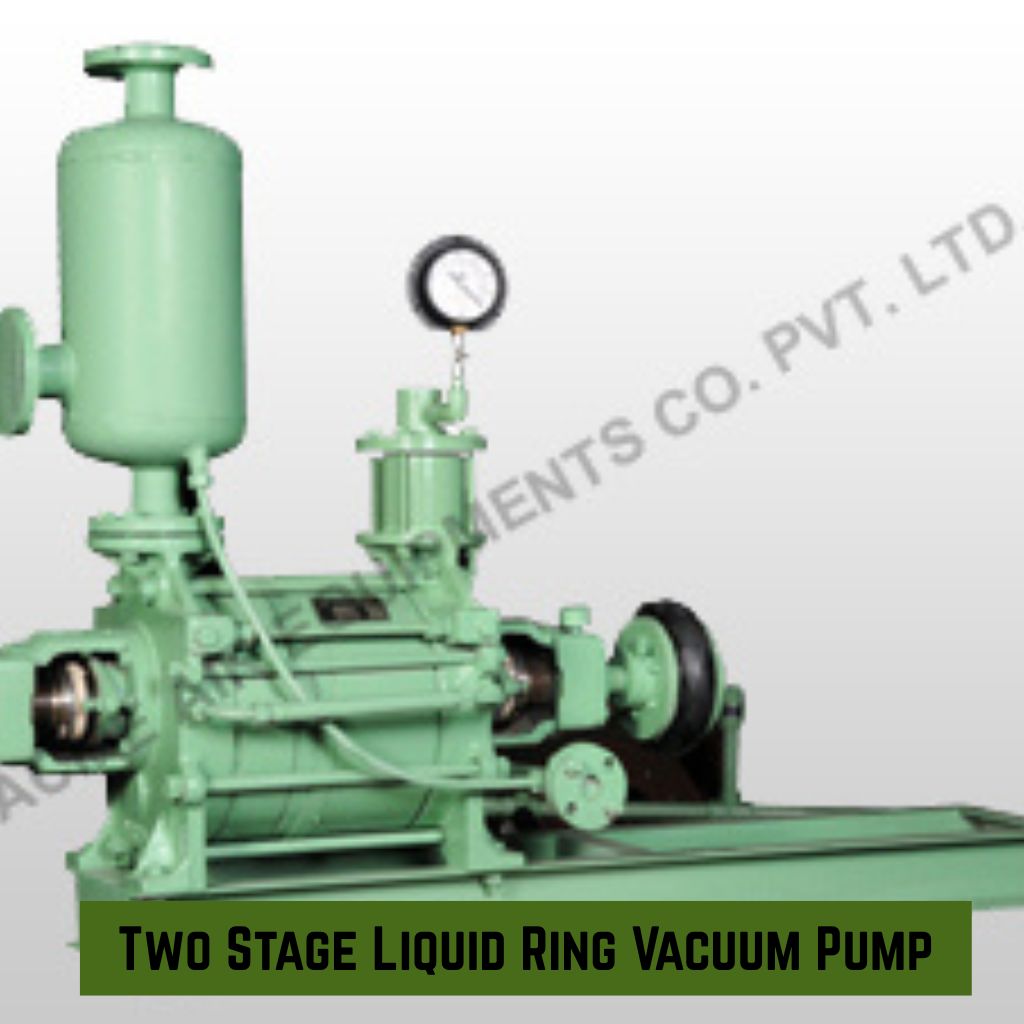

The two-stage liquid ring vacuum pump, as the name suggests, consists of two stages of impellers working in series. This configuration allows these pumps to generate higher vacuum levels and handle larger volumes of vapor and gas compared to single-stage pumps. In Germany, where efficiency and sustainability are paramount, these pumps are integral to the pulp and paper industry’s operations.

How Do Two-Stage Liquid Ring Vacuum Pumps Improve Efficiency in Vacuum Filtration?

Two-stage liquid ring vacuum pumps are designed for high efficiency, particularly when processing substances that require a high level of vacuum. In vacuum filtration, these pumps remove liquid from solid materials, making them essential for operations like pulp washing, dewatering and separation.

Key Advantages of Two-Stage Pumps:

- Better Performance at Higher Vacuum Levels: Two-stage liquid ring vacuum pumps provide a higher vacuum level compared to single-stage pumps, making them more effective for filtration processes that require a deep vacuum. This higher efficiency is crucial for processes in the pulp and paper industry that demand precise control over liquid removal.

- Consistent and Stable Operation: The two-stage design helps in maintaining a consistent vacuum level throughout the filtration process, reducing fluctuations and ensuring that the separation of solids from liquids is both efficient and effective.

- Increased Capacity for Handling Vapors: Two-stage pumps are capable of condensing vapors and gases during operation, which helps in recovering or disposing of process vapors efficiently. This is particularly important in the pulp and paper industry, where volatile organic compounds are often present.

Impact on German Pulp and Paper Facilities:

- Berlin: In major production centers like Berlin, where large-scale pulp and paper mills are located, two-stage liquid ring vacuum pumps enhance the filtration process, ensuring high efficiency and minimizing waste.

- Munich: Munich’s more advanced pulp and paper mills benefit from the high vacuum levels provided by two-stage liquid ring vacuum pumps, helping meet the increasing demand for high-quality paper products.

Why Are Two-Stage Liquid Ring Vacuum Pumps the Preferred Choice for Handling Solvents?

In the pulp and paper industry, solvent recovery is an essential process, particularly in the production of high-quality paper grades. Two-stage liquid ring pumps are preferred when handling solvents at high vacuum levels due to their ability to efficiently condense process vapors.

Solvent Handling Capabilities:

- Enhanced Vacuum Efficiency: Two-stage liquid ring vacuum pumps can maintain higher vacuum levels necessary for solvent recovery, ensuring that solvents are efficiently separated from other materials.

- Minimal Contamination: Because these pumps operate with minimal leakage and are capable of managing vapors effectively, they help reduce contamination risks in the system, which is crucial when working with volatile substances in paper production.

How This Benefits German Pulp and Paper Plants:

- Hamburg: In Hamburg, where many paper mills focus on high-end paper products, the ability to manage solvent recovery efficiently with two stage ring vacuum pumps reduces waste and enhances production quality.

- Frankfurt: Frankfurt’s mills, which handle large volumes of solvent-based materials, benefit from the high performance of two-stage liquid ring pumps, improving both product quality and operational efficiency.

How Does the Two-Stage Liquid Ring Vacuum Pump Design Support High Reliability and Durability?

The robust design of two-stage liquid ring vacuum pumps ensures that they are well-suited for the harsh operating conditions of the pulp and paper industry. With continuous operation and handling of various substances, reliability and durability are essential for minimizing downtime and maintaining efficient production.

Key Features Contributing to Reliability:

- Two-Stage Impeller Design: The two-stage liquid vacuum pump design provides better pressure control and helps distribute the load more evenly across the pump system. This reduces the chances of failure and prolongs the service life of the pump.

- Ability to Handle High Loads: Two-stage liquid ring vacuum pumps are capable of handling high volumes of liquid and gas, making them ideal for the large-scale operations typical in the pulp and paper industry.

- Self-Lubricating and Sealed System: These pumps are designed to work with liquids such as water or specialized oils, which reduce friction and wear, contributing to longer pump life and reducing the need for frequent maintenance.

Impact on German Pulp and Paper Mills:

- Düsseldorf: Pulp and paper mills in Düsseldorf benefit from the long-lasting design of two-stage pumps, ensuring uninterrupted production and reducing the costs associated with maintenance and replacements.

- Cologne: Cologne’s paper production facilities, where high volumes of materials are processed daily, rely on the reliability of two-stage liquid ring vacuum pumps to maintain efficient operations without costly downtime.

How Do Two-Stage Liquid Ring Vacuum Pumps Contribute to Operational Cost Savings?

Operational cost savings are always a priority in large-scale industries and the pulp and paper industry are no exception. Two-stage liquid ring vacuum pumps help in reducing both energy consumption and maintenance costs, which leads to significant savings over time.

Cost-Efficiency Benefits:

- Reduced Energy Consumption: Two-stage vacuum pumps operate more efficiently than single-stage pumps, particularly at high vacuum levels. This translates to reduced energy consumption, helping mills lower their operational costs.

- Lower Maintenance Costs: The durable and reliable design of two-stage liquid ring vacuum pumps means fewer breakdowns and less frequent repairs, reducing overall maintenance costs.

- Optimized Performance: By maintaining consistent vacuum levels and providing better control over the filtration process, these pumps improve system performance, reducing waste and the need for additional resources.

Effect on German Facilities:

- Stuttgart: Paper mills in Stuttgart are experiencing substantial operational savings through the use of two-stage liquid ring vacuum pumps, helping them meet growing demands while keeping production costs under control.

- Leipzig: In Leipzig, where energy costs can be high, the efficiency of two-stage vacuum pumps is helping paper manufacturers reduce their energy consumption, leading to long-term savings.

How Do Two-Stage Liquid Ring Vacuum Pumps Meet the Unique Demands of Germany’s Pulp and Paper Industry?

Germany’s pulp and paper industry faces unique challenges related to scale, product quality and environmental regulations. Two-stage liquid ring vacuum pumps are uniquely suited to meet these demands, thanks to their efficiency, performance and environmental compatibility.

Addressing Industry-Specific Needs:

- Scalability: These pumps are scalable and can easily be adapted to meet the varying requirements of different pulp and paper mills, from small facilities to large-scale operations.

- Environmental Compliance: Two-stage liquid ring vacuum pumps operate with minimal environmental impact, helping facilities meet strict emission standards and reduce the risk of air and water contamination.

Impact on German Pulp and Paper Manufacturers:

- Berlin: In Berlin, where high product quality and efficiency are key, the use of two-stage liquid pumps enables manufacturers to maintain production standards while adhering to environmental regulations.

Bremen: Pulp and paper plants in Bremen benefit from the superior performance of two-stage pumps, which allows them to keep up with the evolving demands of both the local and international markets.

Conclusion

Two-stage liquid ring vacuum pumps play a critical role in optimizing vacuum filtration in Germany’s pulp and paper industry. By offering higher efficiency, consistent performance and reduced maintenance costs, these pumps contribute to the overall operational success of mills across the country. With their ability to handle high vacuum levels, ensure solvent recovery and improve energy efficiency, two-stage liquid ring vacuum pumps are indispensable in maintaining high-quality production standards and supporting Germany’s competitive edge in the global pulp and paper market.

As the demand for high-performance, cost-effective solutions continues to rise, two-stage liquid ring vacuum pumps will remain a key player in driving operational excellence within the pulp and paper industry.

FAQs on Two Stage Liquid Ring Vacuum Pumps

Why are two-stage liquid ring vacuum pumps preferred in Germany’s pulp and paper industry?

Two-stage liquid ring vacuum pumps are preferred because they provide high vacuum efficiency, stable performance and energy savings, which are essential for the demanding filtration processes in the pulp and paper industry.

How do two-stage liquid ring vacuum pumps handle solvent recovery?

These pumps efficiently condense process vapors, helping to recover solvents or dispose of them properly, which is essential in processes where solvents are used in pulp and paper production.

What are the key benefits of using two-stage liquid ring vacuum pumps in Germany’s wastewater treatment at paper mills?

They offer consistent and reliable airflow for aeration in wastewater treatment, reducing energy consumption and minimizing maintenance, which leads to significant operational savings.

How do two-stage liquid ring vacuum pumps reduce operational costs?

By improving energy efficiency and reducing maintenance needs, two-stage pumps lower both energy consumption and repair costs, contributing to substantial savings over time.

Can two-stage liquid ring vacuum pumps be scaled for different sizes of pulp and paper mills in Germany?

Yes, these pumps are highly scalable and can be tailored to meet the specific needs of both small-scale and large-scale operations, making them versatile for various applications in the pulp and paper industry.

About Author

CEO

Mr. Vishwesh Pardeshi is the CEO of Acme Air Equipments Company Pvt. Ltd., an industrial and engineering goods manufacturing company based in Ahmedabad, Gujarat (India). He has taken over the responsibility from founding Partners and Directors of the Company, and is now leading a talented group of professionals since 2020 by bringing in vast industrial and management expertise. By qualification, he holds a Bachelor Degree in Mechanical Engineering and also holds a MBA degree from reputed institutes. Under his leadership, the Company has successfully executed prestigious projects by delivering high quality and world class products from a state of the art manufacturing facility which combines CNC-enabled precision manufacturing and strong after sales support. In line with the Vision, Mission and Core Values of the Organization, Mr. Vishwesh Pardeshi continues to drive Quality, Reliability and Global Expansion at Acme Air Equipments Co. Pvt. Ltd.